10 Sep Bouncing Idle and Mystery Head Bolts

Have you got a tech question that has you stumped? Let us give you a hand.

By Brian Gillepsie

Photos by Carter Gillespie

Recently I put the word out on Facebook to see if anyone had a problem they couldn’t solve. Oneil Lopez posed a question about fixing his idle. He has a ’00 Civic CX hatchback with a ’97 JDM B18C engine. The B18C has a Skunk2 intake manifold and a BLOX throttle body. He’s using an OBD2B-to-OBD1 jumper harness and a P28 ECU chipped on Crome. Oneil says when he lets the car warm up it idles normally, but after he revs the engine past about 4,000 rpm the car won’t idle steadily and keeps bouncing. When he uses a Hondata S300 or stock ECU the problem goes away.

Bouncing Idle

A bouncing idle is a fairly common problem with B-series and D-series engine-swapped Hondas. There are three likely causes for this problem, and they probably don’t have to do with the ECU. Most of the time a bouncing idle is caused by the idle not being set correctly. The second and third most common causes are a fast idle valve problem or a vacuum leak. The stock ECU and Hondata’s S300 may do a slightly better job at controlling the idle, but there’s no reason the Crome-modified ECU can’t also.

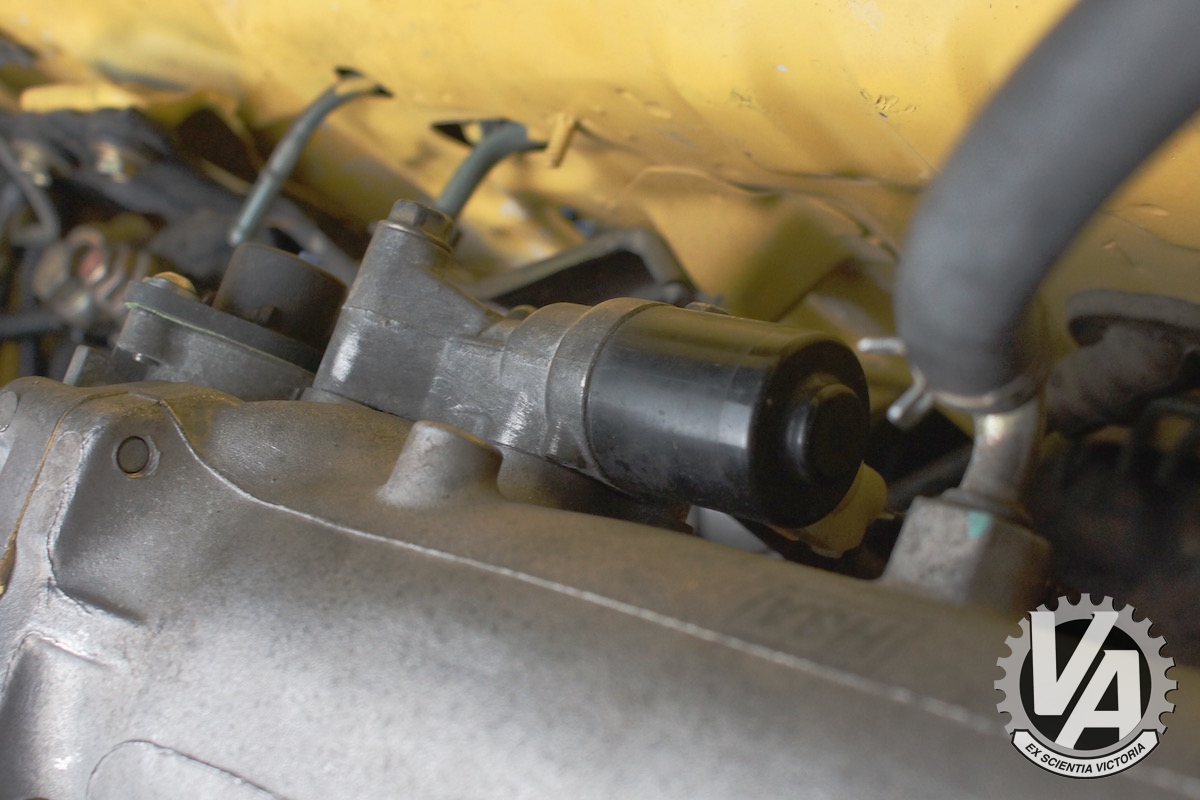

Let’s start with setting the idle properly. Oneil sent me a video of the car idling. According to the video the car was idling at 1,000 rpm after it was warmed up. That’s actually a little too fast and can cause the bouncing idle. When warm it should idle below 800 rpm, so let’s start by setting the base idle. First warm up the car until the radiator cooling fan turns on. Now unplug the EACV (engine air control valve); that’s the valve assembly on the back side of the intake manifold near the firewall with the round electrical connector. Unplugged you’ll get a check engine light, but don’t worry, we’ll fix that in a bit.

The IACV sits on the back side of the intake manifold of the B and D-series engines, and the front side of the H-series engines. To disable it, pull the two pin round plug off the IACV. It will throw an error code, so you will need to reset your ECU after you are all done. It's the whitish colored plug hang out the bottom of the IACV in this picture.

With the EACV disconnected the ECU can no longer control engine speed, which means you can set base idle using the idle set screw. Turn the screw clockwise to bring the idle down to about 500 rpm. If you can’t get it down to 500, then you have a problem with either the fast idle valve or a vacuum leak. If it’s below 500 and you can’t get it to come up, then the throttle body or idle port is dirty and needs to be cleaned. Once you’ve set the idle turn the engine off and plug in the EACV. Now reset the ECU; you can do this by removing the negative cable from the battery for five or 10 seconds. This will also get rid of the check engine light. With the ECU reset, start the car and let it idle without the A/C on until the cooling fan cycles on a couple of times. If the idle still bounces after revving it, continue on with the next steps.

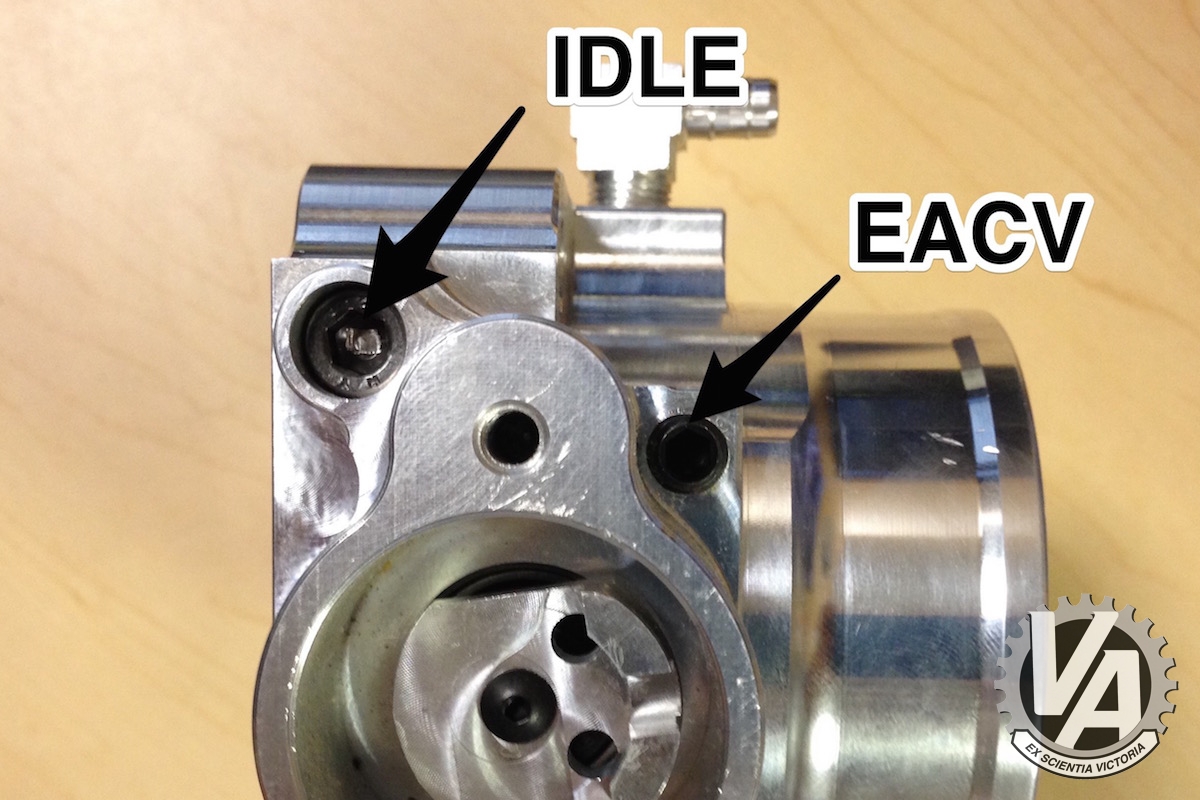

Oniel has a BLOX throttle body. Here’s some information specifically about that brand of throttle body. There are two screws on the throttle body that can be used to adjust the idle. One, of course, is the idle set screw and the other can be used to fine tune the air getting to the EACV. If you get the idle close to 500 rpm but it still bounces after you reconnect the EACV, try adjusting the EACV air screw. It may help you get the right idle speed.

Also, if the throttle plate stop screw is out of adjustment, it can hold the throttle plate open slightly and air will leak by raising the idle. You might want to take the throttle body off and check if there are any openings around the throttle plate letting air through. Hold it up to a bright light and see if there is a gap between the plate and the inside of the throttle body.

If you aren’t able to get the idle down to 500 rpm, then you might have a bad fast idle valve or a vacuum leak. Like the Integra Type R’s, the BLOX throttle body has no fast idle valve. Still, someone reading this article might, so I’ll go over the procedure for troubleshooting the fast idle valve. B-series and some D-series engines built before 1996 and all H-series engines have a fast idle valve. If your car has a fast idle valve, it bolts to the bottom of the throttle body or to the manifold underneath the throttle body.

Here’s a quick test to see if it’s the problem: With the engine warmed up and the intake air tube off of the throttle body, use your finger to plug the hole that feeds air to the fast idle valve. It’s usually the bottom hole. With the car warmed up, there shouldn’t be any air passing through the port. You’ll be able to feel it if there is.

The purpose of the fast idle valve is to let in extra air to smooth the idle until the engine heats up. It’s set at the factory and is considered a non-serviceable part. Inside there’s a plunger controlled by the temperature of the coolant that lets air bypass to boost idle. Sometimes it comes unscrewed and lets air in when it should be closed. If you remove the end cap from the fast idle valve, you can screw the plunger down until it bottoms out. That fixes the problem.

If the fast idle valve isn’t a problem, then you most likely have a vacuum leak. A quick test for vacuum leak is to place your finger over both the fast idle valve port and the idle port (which feeds the EACV, too) in the throttle body. The engine should die immediately; if the car continues to run at all, you have a leak. The vacuum leak can come from many things, including: torn or cracked vacuum lines, bad gaskets or seals at the throttle body, manifold, EACV, fast idle valve, or injectors. It can also be caused by loose bolts around the intake manifold or throttle body or even a bad brake booster

There are a lot of ways to determine where a vacuum leak is. Brake cleaner, propane, and smoke can all be used to see where air is getting into the manifold. B-series and D-series engines built before 1996 have a fast idle valve. Some of these techniques can result in a fire though, so I’ll let you choose which one you feel comfortable using. Check out YouTube for more information. Do yourself a favor and keep a fire extinguisher on hand if you are choosing a flammable substance to find the leak. I’ve usually been able to find the leak by closely inspecting the manifold and surrounding parts.

On very rare occasions the EACV is the problem and needs replacing. It can get stuck in an open position. If nothing else brings the idle down, you can remove the EACV and plug its port into the manifold to see if it drops the idle. That will tell you for sure. Anyways, with these steps you should be able to find the problem. Good luck, Oneil.

Mystery Head Bolts

Alex Naranjo also wrote in; he has a question about ARP head studs. He bought a set for his R18A1 engine and wanted to know the proper torque specs for the studs. ARP, or Automotive Racing Products, is the go-to source for bolts, studs, and other fasteners for racing applications. They make head studs, rod bolts, and main studs for a lot of B-series and K-series engines. A quick look at the company’s website revealed that there was no head stud kit for R18 engines, so I asked Alex for a part number on the studs. The part number he gave me was ATP80001LUB.

After a little sleuthing I found out the ARP head studs he had came from the B18A head stud kit. The B18A/B has two long studs and eight short ones. It just so happens someone has packaged 10 of the longer studs together and calls it an R18 head stud kit. This is kind of cool because the R18 studs will also work for the newer K24 found in the Accord and TSX. The torque spec for the bolts are 70 lb-ft.

Have you got a question for the experts at VTEC Academy? Do you have a problem you haven’t been able to solve? Bring us your toughest questions and we will do our best to answer them.

No Comments