26 Jan S2000 K Swap

S2000 K Swap: Blasphemy or the Next Big Thing?

By Brian Gillespie

Photos by Loi Song

Video by Aaron Gaghagen

When Honda dropped the AP1 S2000 on us back at the turn of the century, it was the baddest Honda you could buy. Yes, there was the Integra Type R and the NSX, but the Type R felt familiar and the NSX was a bit long in the tooth. The S2000 was new and a departure from what Honda was doing at the time. It was the buffed-out convertible that looked as good as it went. As good as the Mazda Miata (yuck-AG) handled, it was always kind of a rag top punchline for most people. That wasn’t the case with the S2000. It was a rear-wheel-drive, front-engine driver’s car. The manual transmission that it was only available with shifted with razor-like precision. Honda didn’t water the S2000 down with an automatic transmission like other manufacturers would do. No, this was the car for people who “got it.”

Then there was the engine; the S2000’s 2.0L F20C1 had the highest specific horsepower output of any naturally aspirated mass-production engine ever. It begged to be revved to the high heavens like all great VTEC powerplants. And then with the AP2 S2000 displacement was bumped to 2.2L, giving it more torque and making it a bit more forgiving for drivers who didn’t want to keep it at 9,000 RPM all the time. And people loved it.

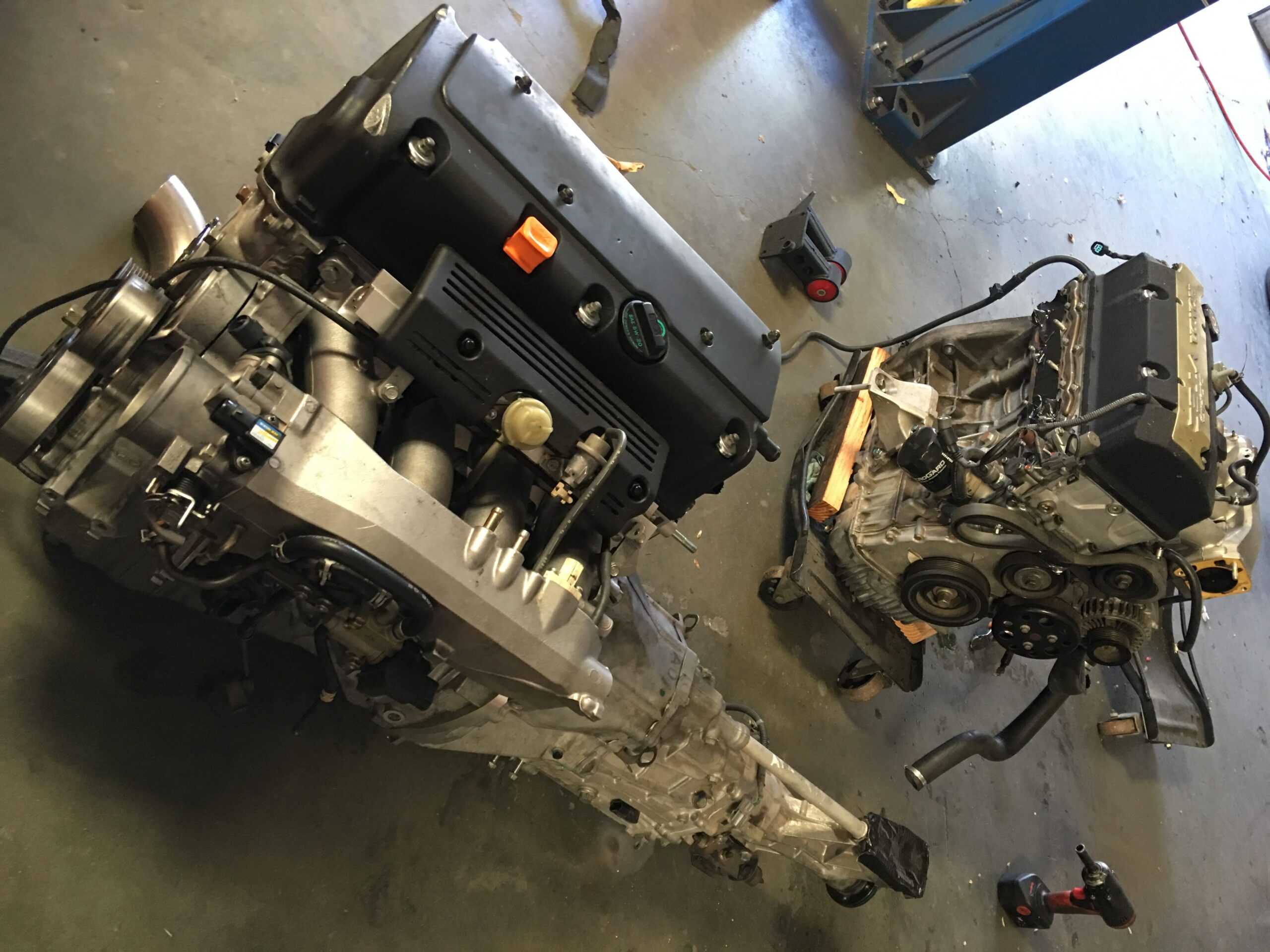

So, if the F20C1 and F22C1 are such great engines, then why would anyone in their right mind ever think about swapping in a K-series engine? First, K-series engines are cheaper than F-series engines. Honda and Acura put Ks in millions of vehicles over a wide range of models whereas the Fs (not including older F-series that were in Accords and Preludes) were only put in S2000s. Second, there are more tuning options for the K-series. From headers to intakes to cams to pistons to rods to you name it, it’s all available for the K from many different sources.

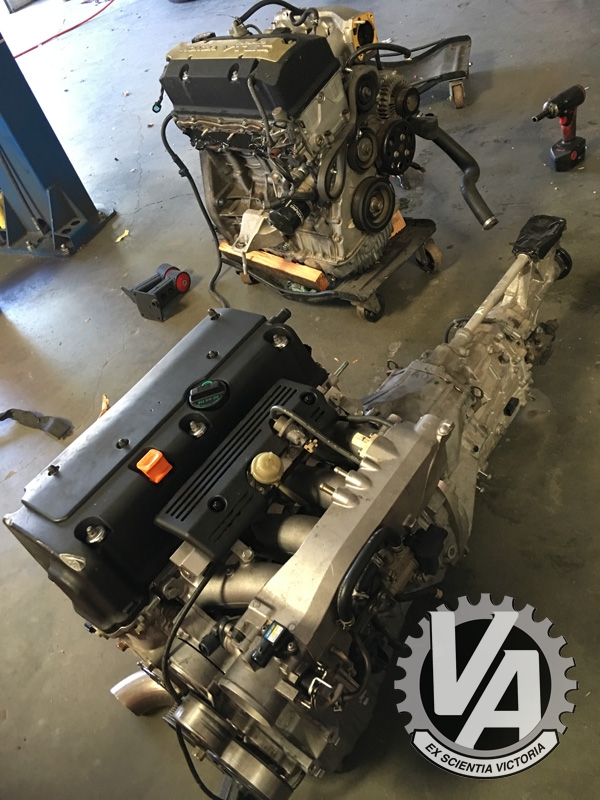

The S2000 here is Loi Song’s from Sportcar Motion. His F22C1 blew while racing and he decided it was time to take the road less traveled by S2000 owners by going with a K24A2 using the Hasport Performance APK2 kit. He can make more horsepower with the K-series and with a bunch more torque. Hell, even if the F-series was in perfect shape, a K swap could be the smart move for racers. You could take out the more expensive engine, race with the K swap, and save the wear and tear on your F-series.

Prepping the engine

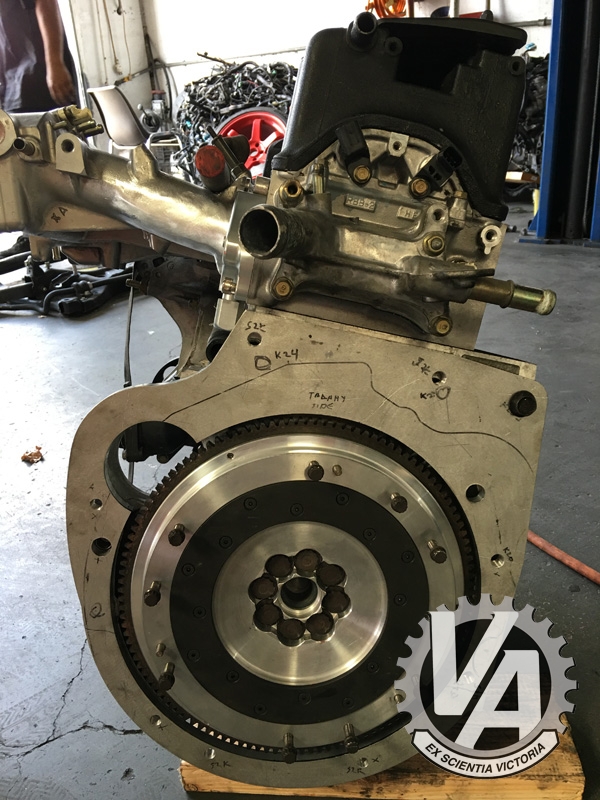

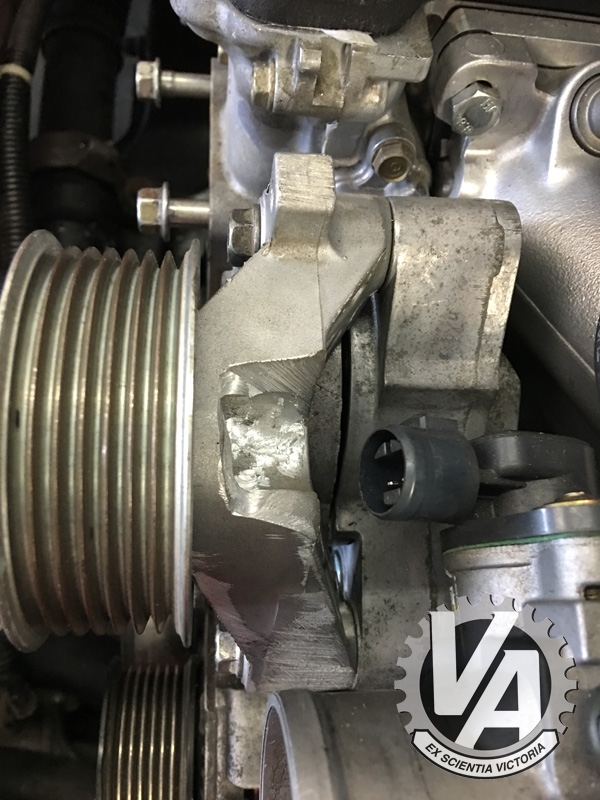

The swap starts with this. This is a F2K transmission adapter plate. Its made by Ballade Sports. Without it, you can't mount the engine to the transmission. Get yours at http://www.balladesports.com

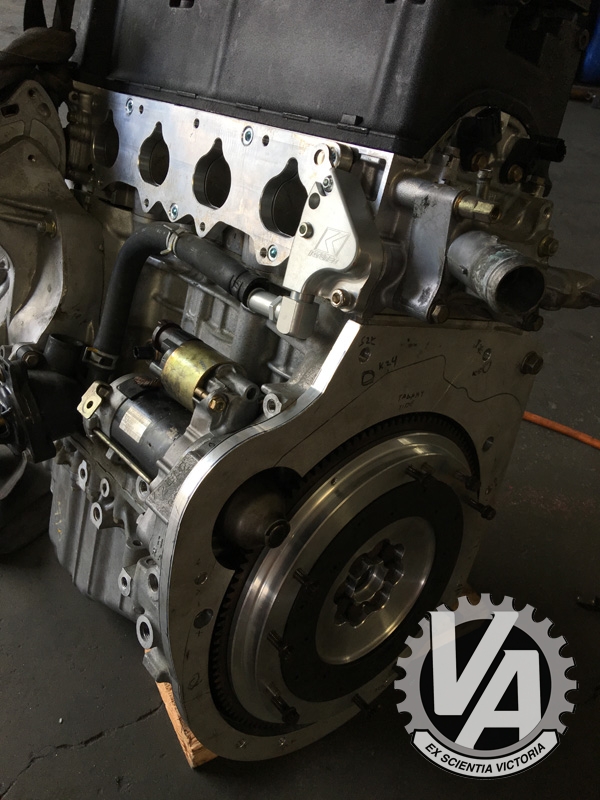

Along with the adapter plate a key part of the swap is a Clutchmasters K to F flywheel. The clutch plate contact ring is spaced a half inch to compensate for the half inch thick adapter plate for the transmission. You can't just put a half inch spacer behind the stock flywheel. That would move the ring gear away from the starter and it would no longer be able to engage it.

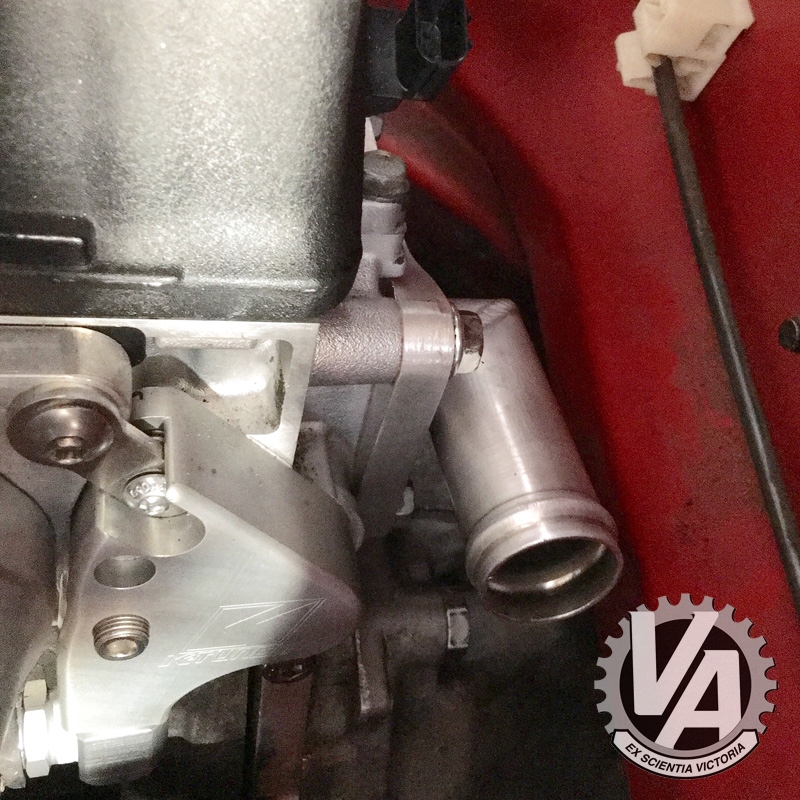

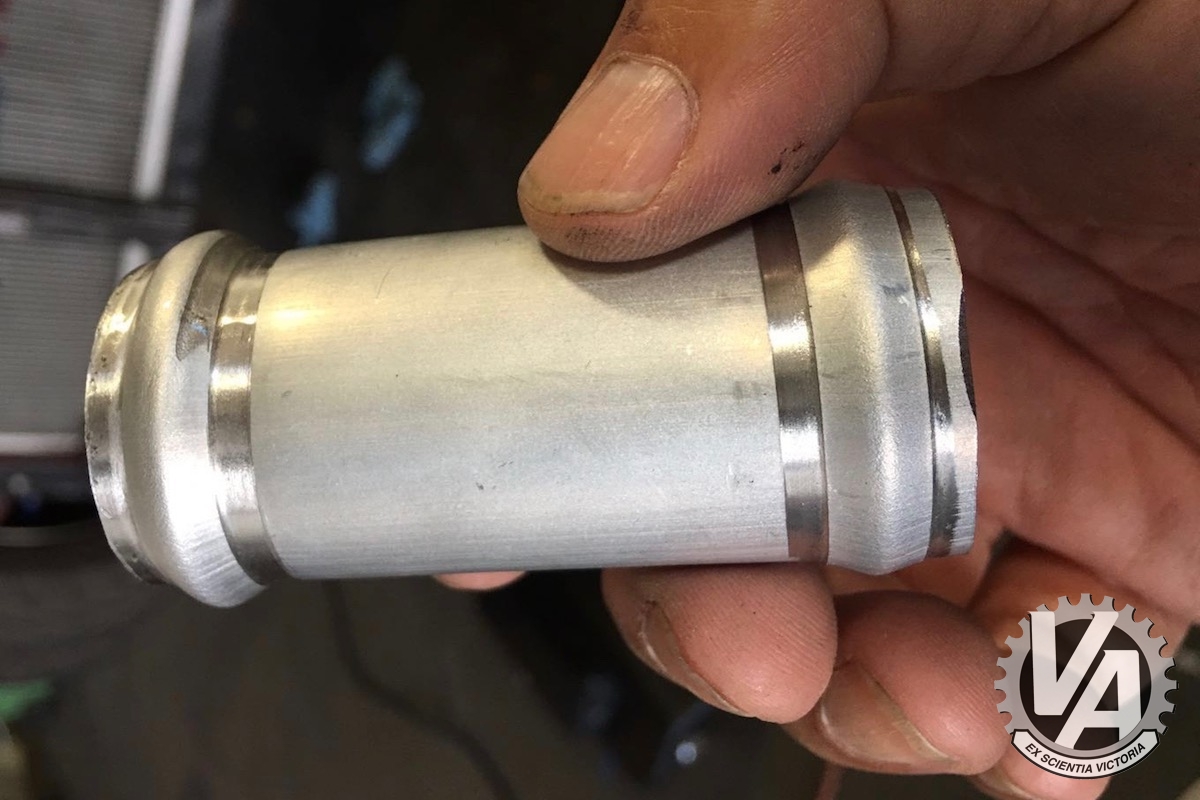

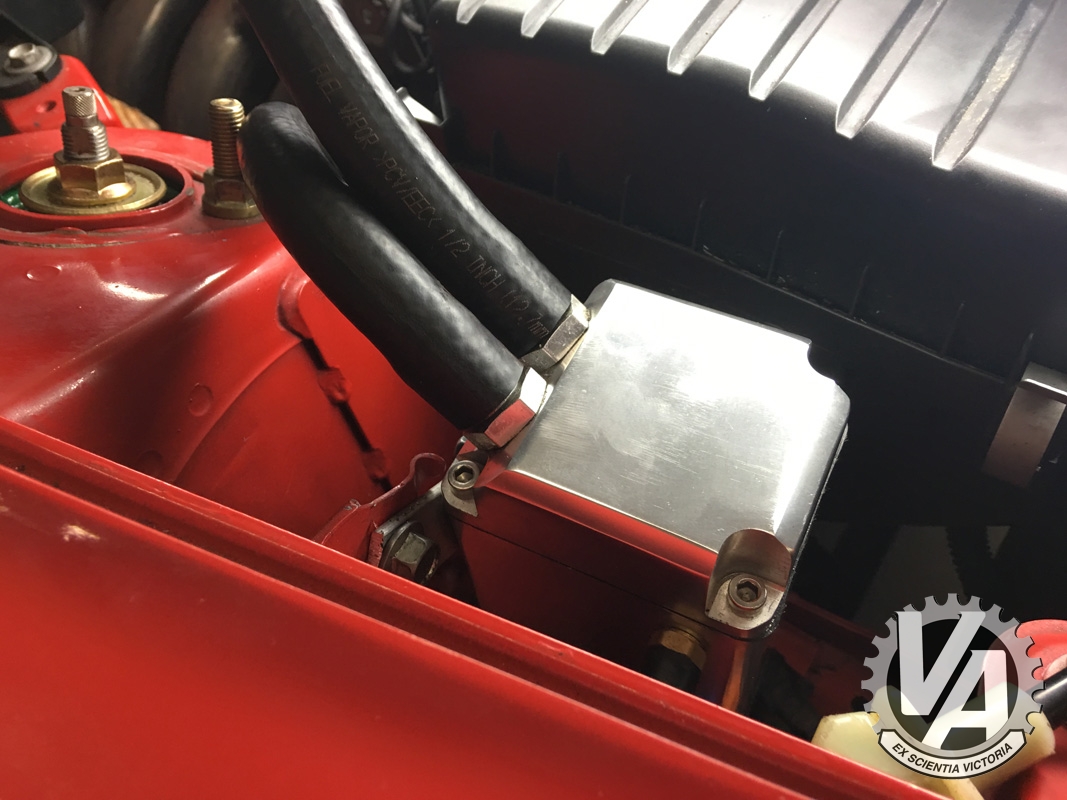

JSP Fab makes the intake manifold adapter so you can bolt the F20 intake manifolds on the K-series engine. The intake manifold adapter is designed to be used with the K20 head found on the RSX. If you have a TSX style head you'll also need this adapter for the thermostat water bypass hose. This one is made by K-Tuned.

Mount up!

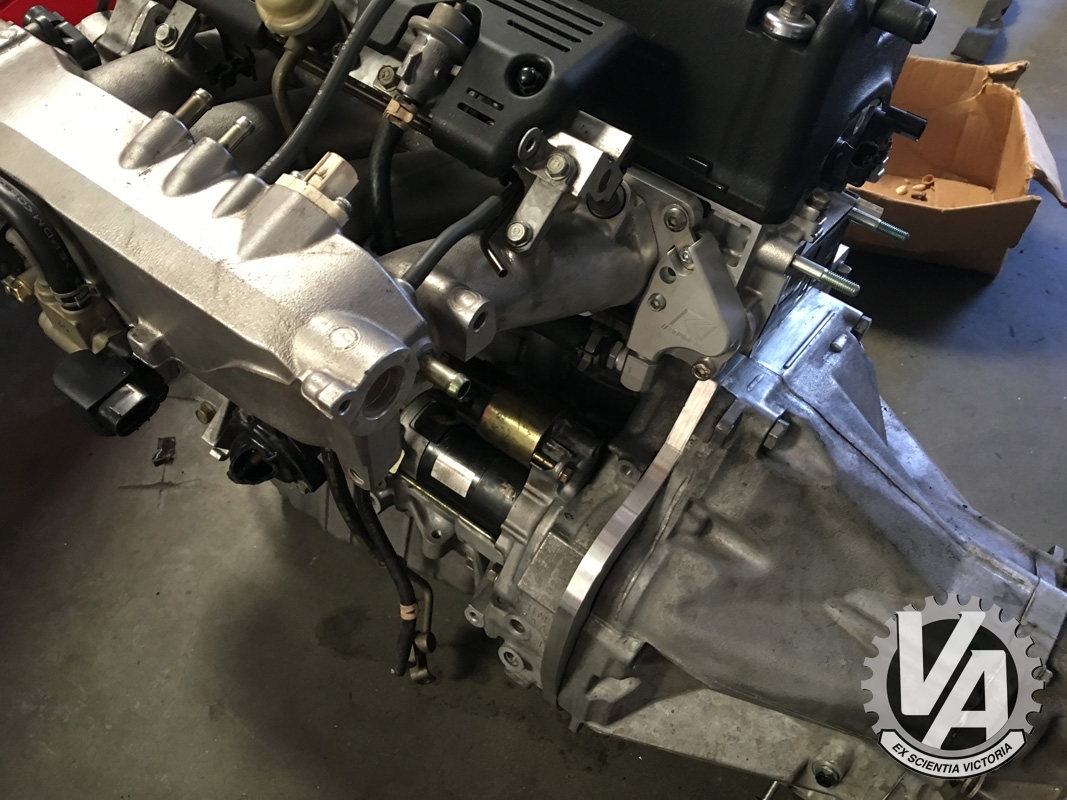

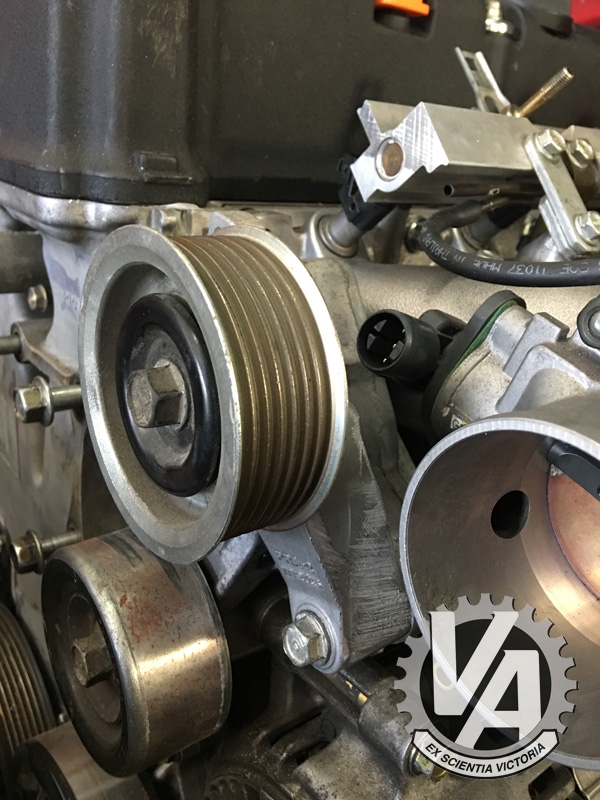

The Hasport APK2 K-series swap kit uses mounts on each side like the stock mounts. Also, it's dual height. In the higher position is identical to the stock height of the F20. The lower position the valve cover clear the hood and the head on the taller K24 stays in virtually the same position as the K20 head. Headers, intakes and turbo manifolds fit in the same position in the car regardless of which engine is used. The stock rear mount is used with the kit.

You can see in the picture of the right-hand mount, there are two mount holes for mounting the engine at different heights. The lower hole if for K20 engines and the upper hole is for the taller K24. The dual height, eliminates the need for different turbo kits for the K20 and K24 blocks. The parts fit the same regardless of the block.

210

Which Wire Where Scare

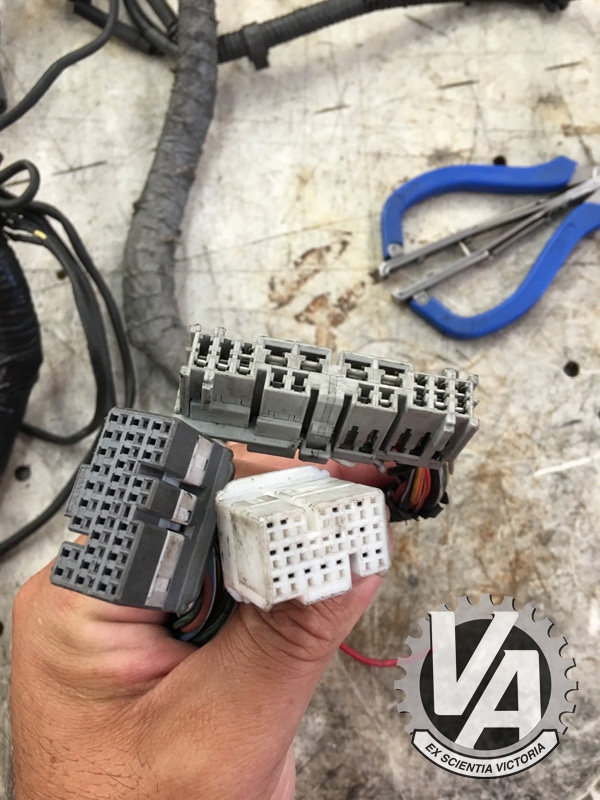

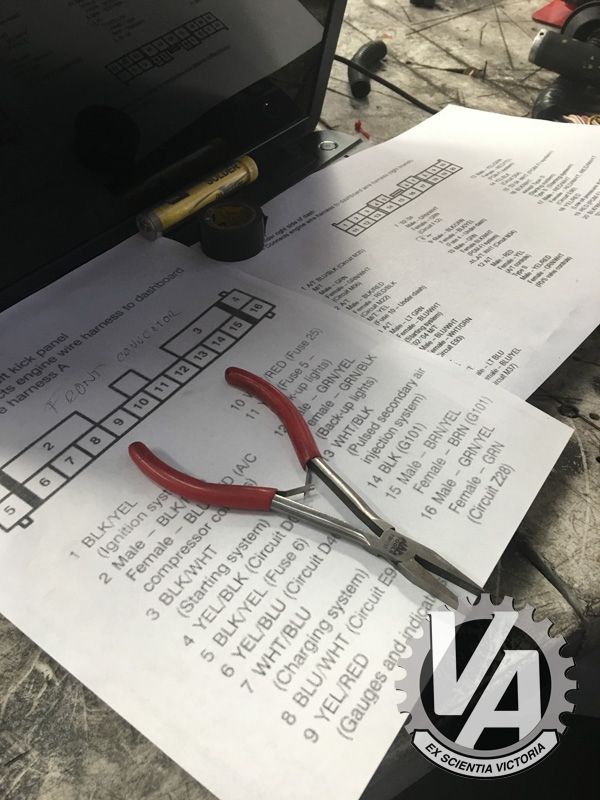

This is the an RSX and S2000 engine harnesses. The two must become one so they can be stronger than the sum of their individual parts. Sounds kind of Zen doesn't it. The wiring is actually the hardest part of this engine swap. The RSX harness gets modified to work with the S2000 body harness and the one ECU plug that is connected to the body harness needs to be modified to work with the Hondata K-Pro ECU.

Along with TPS and MAP sensor plugs getting lengthened on the harness the vehicle speed sensor connector is modified. The RSX's VSS uses 12V to power the sensor, the S2000 uses a 5V powered CSS with a different connector. Then that needs to be lengthened to reach back to transmission. The electronic idle control valve and intake air temp wires need to be lengthened too.

Rad Man

A Breath of Fresh Air

502

Venting

In Conclusion…

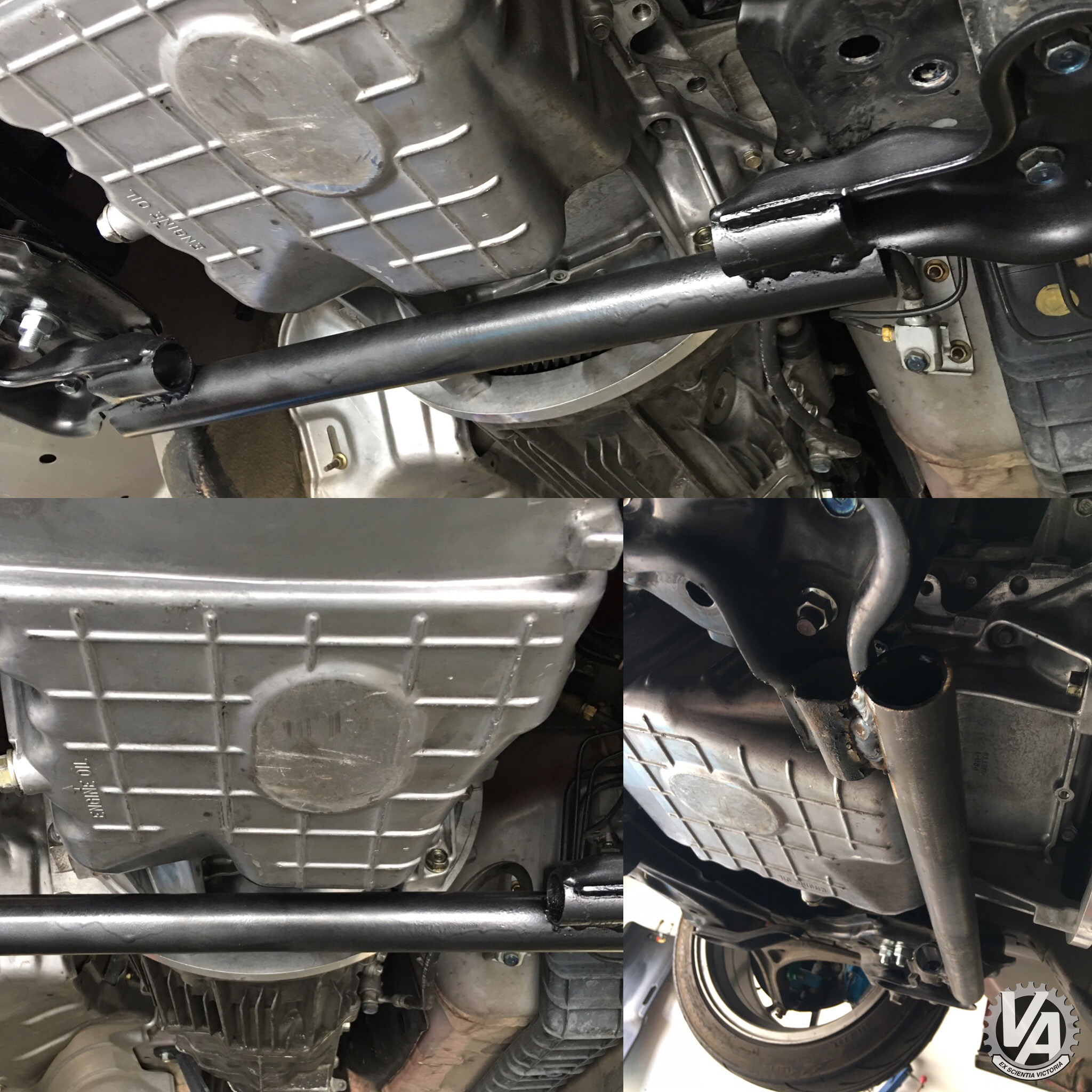

We went with Loi to Dardan Tuning to see what his S2000’s new power plant would put down on the dyno. With some tuning this engine has the potential to do way more than what the original F22 could ever hope for with the same level of modification.

Like us? Help Support VTEC Academy by hitting up our store for gear at https://vtec.academy/shop/ or help us by sharing (it’s free!) this post or others with other cool Honda people.

Nothing but Hondas. That’s exactly what you’ll find at VTEC Academy. Not because some of the other automakers’ cars that inherently drain the life out of the driving experience bore us, but because Soichiro Honda’s passion for motorsports and his company’s ability to express that in the machines they produce make a whole lot of sense.

VTEC Academy is a place for Honda fans who feel the same way and who seek the most accurate technical information and commentary to continue that very legacy and make whatever Honda it is that they drive just a little bit better. And faster.

The editors and contributors of VTEC Academy are some of the industry’s most experienced and trusted, which means the informative, unique perspectives you need are all right here. And, like you, we’re also obsessed with Hondas.

So, subscribe to our channel and hit us up at vtecacademy.com or, if you’re into social media, you can get your daily dose of VTEC Academy on Instagram, Facebook and Twitter. We’re always on the look out for cool and fast Hondas.

No Comments